This DJ Mixer repair was a bit of a departure for me, but I did it for an old customer.

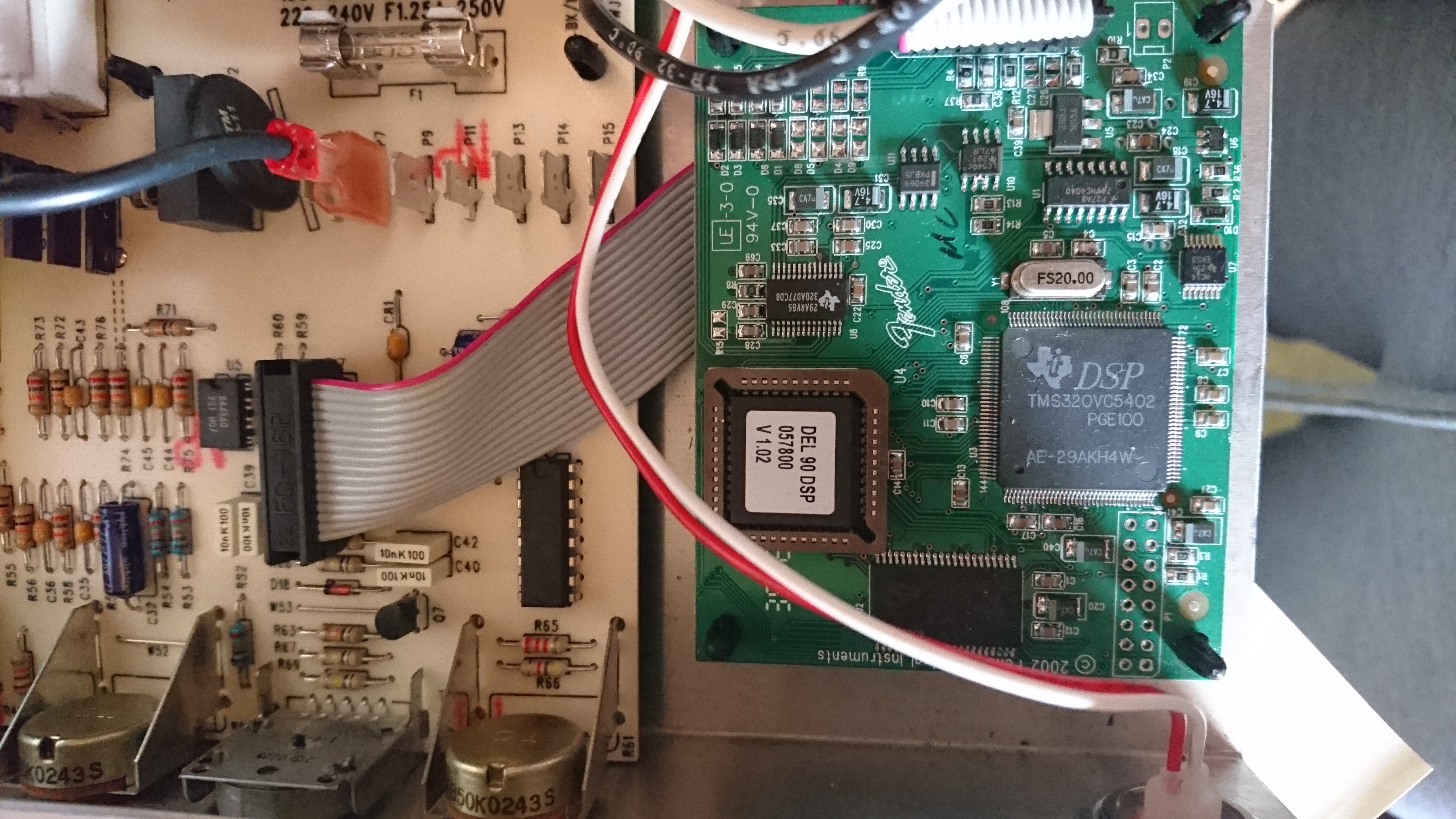

The mixer is getting a bit long in the tooth: the send and PFL (pre fade listen) buttons were intermittent, the faders were scratchy and an intermittent fault with the echo unit.

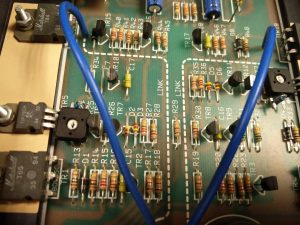

The faders were easy – they simply need contact cleaner spraying inside. However one fader (mic 3) exhibited crackle even after cleaning. It didn’t sound like dirt, so I investigated further.

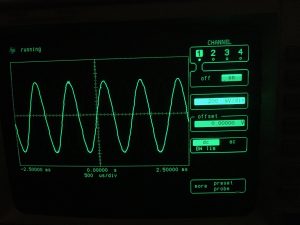

Upon investigating the issues with the echo and the mic3 fader I discovered that the board had several dry and cracked solder joints. Some joints just had very fine hairline cracks. I repaired the broken joints which fixed the mic3 and echo issues and I was able to identify that a certain pad to pin hole ratio was particularly problematic. This allowed me to take preventative action on similar sized joints across the board.

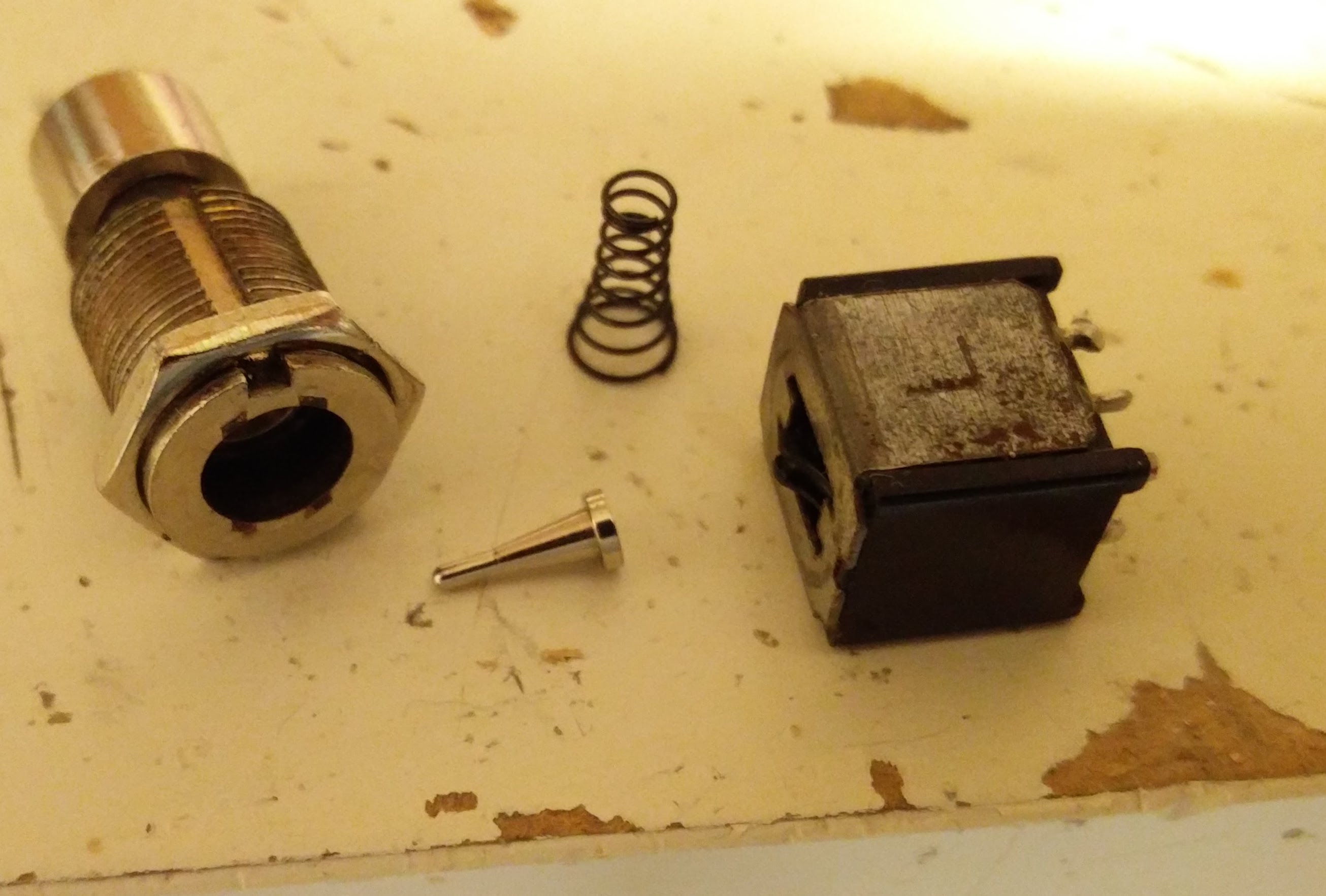

The next task was to fix the faulty intermittent PFL and Send switches. This required complete disassembly to allow the spraying of contact cleaner into the switches. The biggest challenge with a unit like this isn’t technical – it’s just the time it takes to remove the 50+ knobs and switches!

The image is a stcok image as I didn’t take a photo this time.

If you have a dj mixer repair, please get in touch via the contact page.