This Peavey Classic 30 repair was a bit of a nightmare!

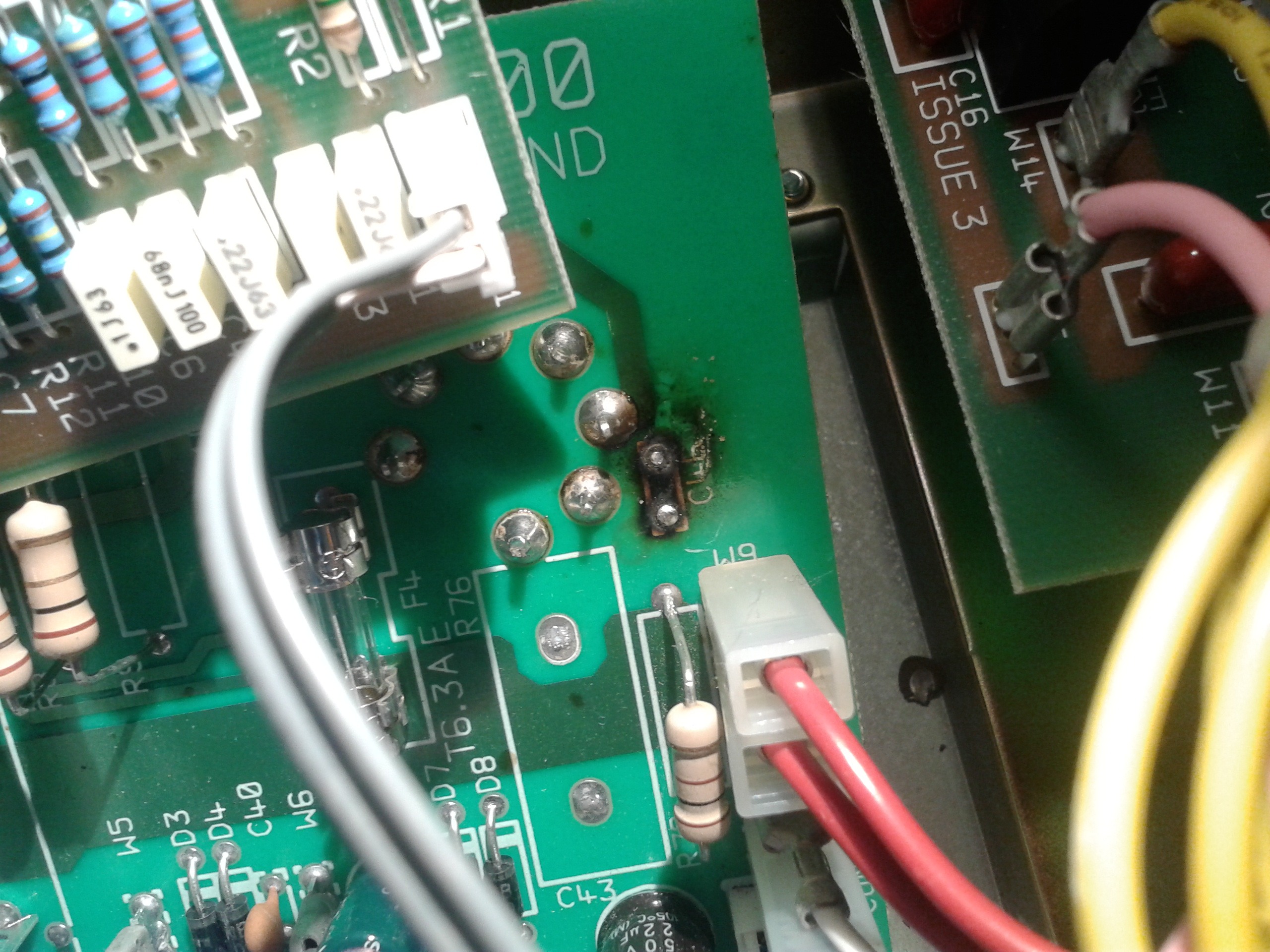

It arrived with a fairly basic problem – the amp wouldn’t turn on. This was down to a loose screw. It held the mains fuse holder internally. When this came loose, the fuse holder was dangling in mid air and shorted mains directly to the metal case of the unit, which caused the fuse to blow – which is a good thing!

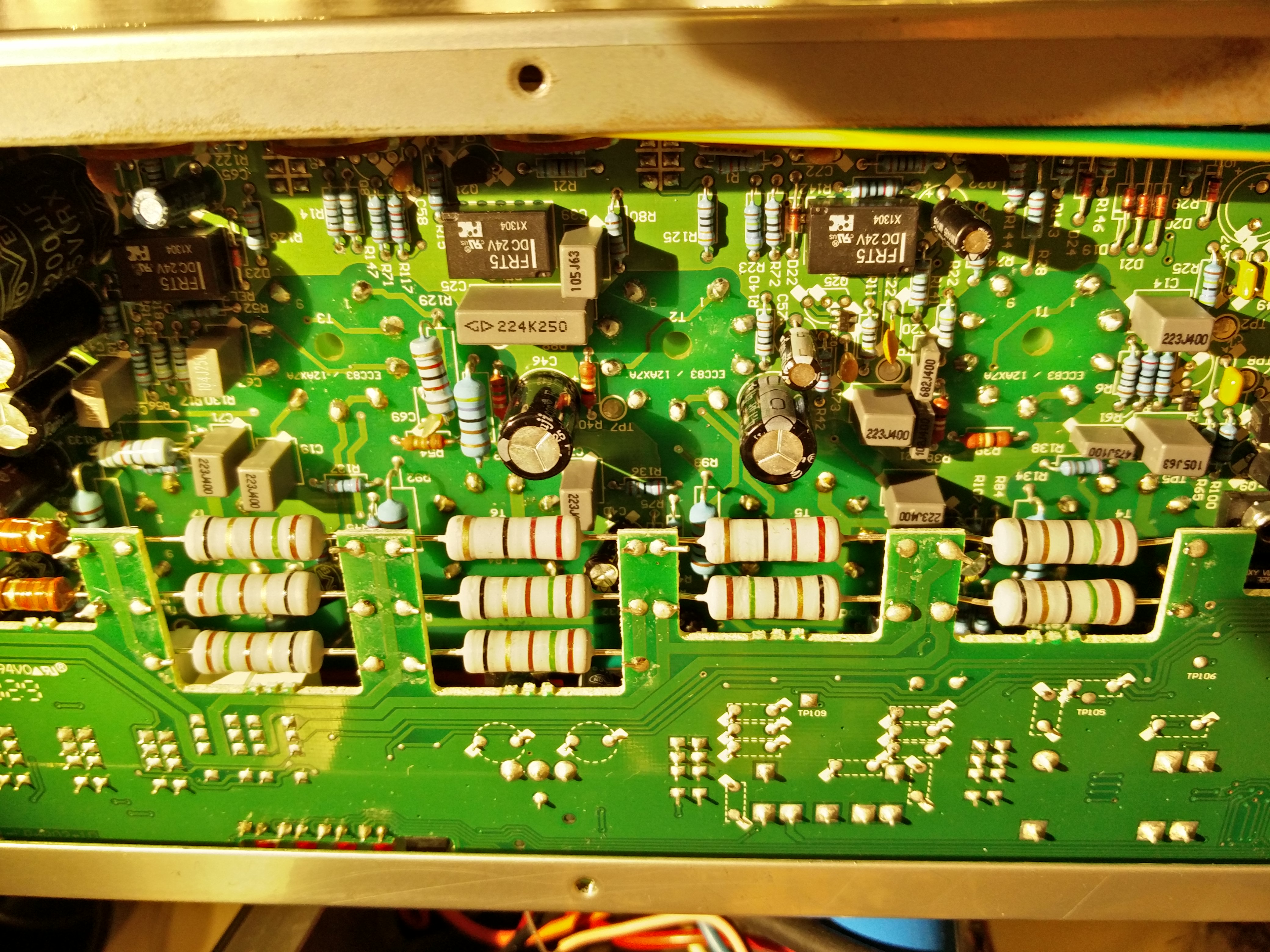

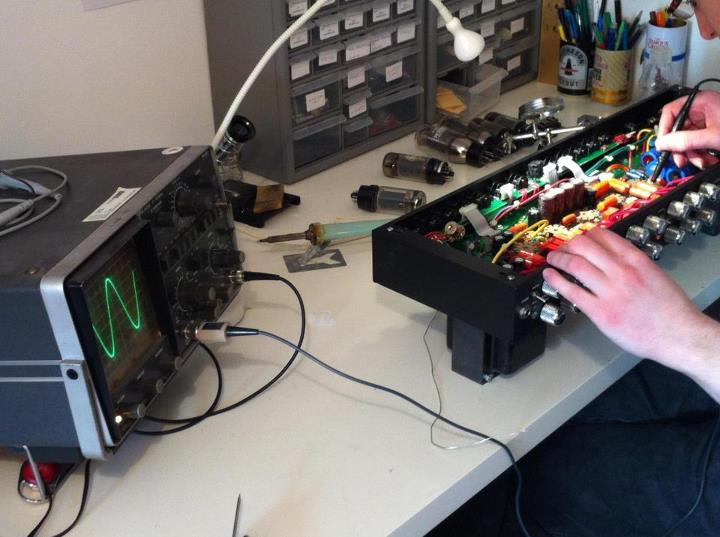

I spent an hour on it – tested all the valves and checked the plate and other power supply chain elements – all the preamp valves are good, but the inner power amp valves no longer match so I changed these. There was no means of adjusting the bias so it’s a question of juggling valves until I find a set of EL84s that properly bias.

I then soak tested the amp. This involves running the amp at gigging voltages with a pink noise signal for a couple of hours. I do this to check that there aren’t any problems with the amp that only appear after a longer period.

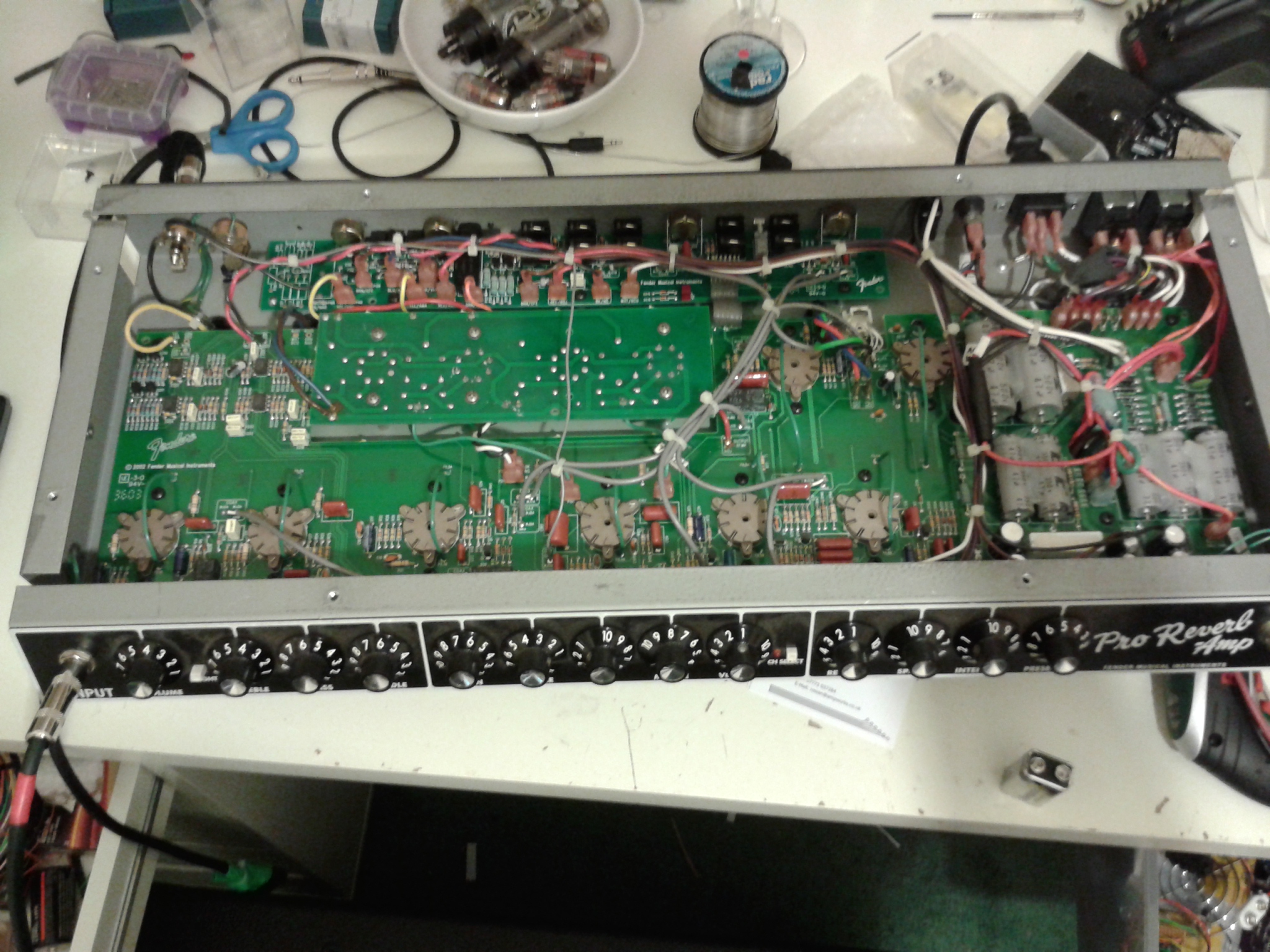

In this case, the amp started making a crackling noise after the two hour soak. This turned out to have a twofold cause – there was a leaking cap in the tone stack and the HT electrolytics (IC brand) were also worn.

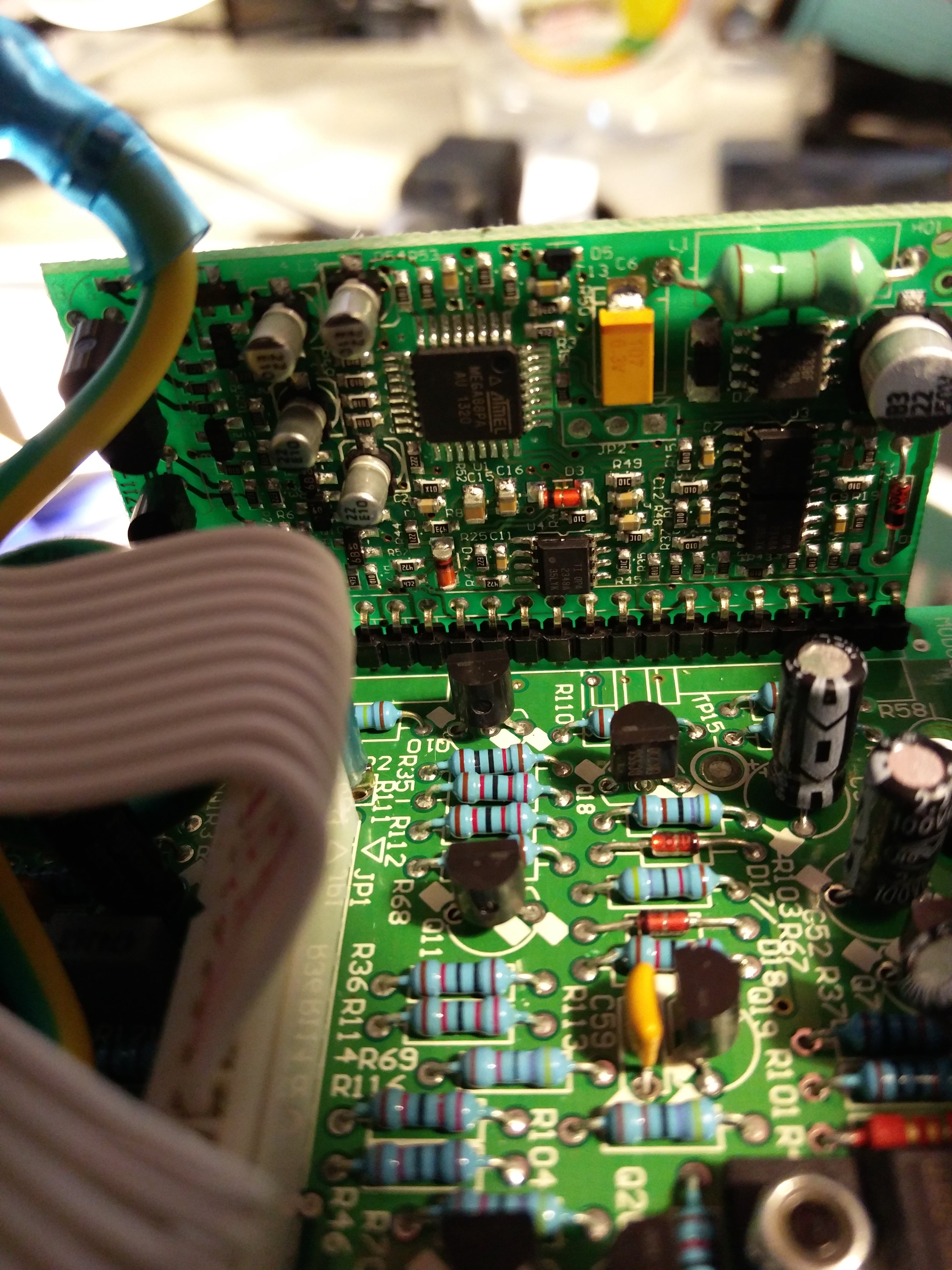

Unfortunately the design of these early peavey Classic 30 amps uses single wire links between the boards. It’s a nightmare to disassemble and these little wire links are a common cause of failure. This slowed down the diagnostic quite severely

If you need a peavey classic 30 repair, please do contact me.