Most of the valve testing that I do is as a routine part of the service and repair of valve amps. There is NO CHARGE for the testing of valves as a part of a repair and valve testing is included in every valve amp service. However I’m approached from time to time by people who just want valves testing either to sell or for peace of mind. Valve testing is charged per valve, the price depends on the service you require. There’s a minimum charge of £16 for valve testing when not performed as part of a service. There are 3 valve testing services currently available. Test certificates are available as part of all of the services. For large quantity valve testing requirements I’m happy to negotiate a reduced rate.

If you’re bringing me a repair and you have a couple of old valves you’d like me to test then no worries, that’s FOC and I can use them for the repair if they’re still good. If you’ve got a whole box, I may charge though!

Advanced Valve testing (£8/valve)

This new service uses a Ronald Dekker uTracer 3+ curve tracer. This is a digitally controlled curve tracer. This unit gives the following advantages:

- Anode (plate) current tracing

- Super accurate power valve matching at a range of realistic anode voltages

- Test any octal or noval valve

- Accurate Ia (Ip) value for a given anode and grid voltage

- Accurate transconductance (gm) calculation across a wide range of grid voltages

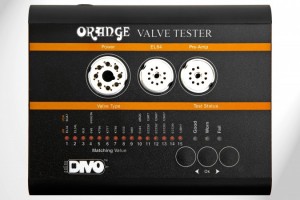

Basic Digital Valve testing (£4/valve)

Basic digital valve testing is performed with an Orange VT1000 valve tester. There are more advanced valve testers around, and I’ve used traditional units by Avo in the past but this does exactly what I need at Ampworks. It tells me if the valve works and whether it’s suitable for the customer’s amp. This is a digitally controlled basic valve tester that gives a pass/worn/fail result as well as a matching value to allow the grouping of power valves into matched pairs or matched quads (or matched duodecads like this mesa boogie bass 400+ repair!). If you’re testing a dual triode then it gives a matching value for each triode, allowing you to determine if a valve is suitable for phase inverter duties. It’s not possible to test some valves on the VT1000, these must be tested on the advanced service.

Basic digital valve testing is performed with an Orange VT1000 valve tester. There are more advanced valve testers around, and I’ve used traditional units by Avo in the past but this does exactly what I need at Ampworks. It tells me if the valve works and whether it’s suitable for the customer’s amp. This is a digitally controlled basic valve tester that gives a pass/worn/fail result as well as a matching value to allow the grouping of power valves into matched pairs or matched quads (or matched duodecads like this mesa boogie bass 400+ repair!). If you’re testing a dual triode then it gives a matching value for each triode, allowing you to determine if a valve is suitable for phase inverter duties. It’s not possible to test some valves on the VT1000, these must be tested on the advanced service.

The VT1000 performs the following tests:

VT1000 Valve tests:

- Heater filament test: Short circuit

- Heater filament test: Open circuit

- Heater filament test: Tolerance check

- Heater cathode insulation: Leakage

- Heater cathode insulation: Short Circuit

- Tests for heater current abnormalities

- Amplification factor

- Voltage gain

- Power gain

- Screen grid test

- Mutual conductance test

- Dual test for double triodes

- Emission

- Inter electrode leakage

- Inter electrode short circuit

- Flash-over (arc detection, high voltage breakdown)

- Gas ionisation test

Valve/tube types

I can test the following valve/tubes (Datasheets available from http://www.r-type.org/):

Octal power tube testing (pentodes and tetrodes):

- EL34/6CA7;

- EL34L;

- 6L6;

- 6V6/6V6GTA;

- KT66;

- KT77;

- KT88;

- 6550;

- 5881;

Noval power tube testing (pentodes):

- EL84/6BQ5;

- 7819 (Advanced service only)

- EL84-M (Advanced service only)

Noval preamp valve testing (dual triode):

- ECC81/12AT7;

- ECC82/12AU7;

- ECC83/12AX7;

- ECC99;

- 12BH7

Noval preamp valve testing (pentode)

- EF86 (Advanced service only)

Valve rectifier testing (Advanced service only)

- 5U4GB (5U4G) (Advanced service only)

- GZ34 (5AR4) (Advanced service only)

- GZ32 (5AQ4 – CV593 – 52KU – 5V4G – 5Z4G) (Advanced valve testing only)

- EZ81 (6CA4) (Advanced service only)

- 5Y3 (Advanced service only)

Other ‘basic’ testing (£8)

If your valve type isn’t listed then I can probably still test it, a basic digital or advanced digital test can be performed on nearly all the valves that are commonly available on valve amps from the late 1950s onwards. However, these tests are only suitable for noval (B9A) and octal valve types. For other valve types such as 7 pin, loctal, Duodecar, Rimlock etc, I also do a ‘basic’ test that checks basic function but cannot guarantee valve performance.

- Heater test: Apply the rated heater voltage to the filaments, check the current draw and ensure filaments are glowing.

- LV DC short test: Multimeter test to ensure that no pins (except filaments) measure a low resistance at DC. Low voltage, does not run the valves at rated anode voltages.

I’ve done these basic tests on:

MKT4/7 ( 7 pin Beam Tetrode) Sensibly equivalent to:- 7A2 – AC/Pen – APP4A – CV1683 – MP/Pen – KT42 – Pen4VA – A70B – N40 – P4VA

B65 (Octal Dual Triode) Sensibly equivalent to:- 13D2 – 6SN7GT – CV1988 – ECC32

B36 (Dual Triode) Sensibly equivalent to:- 12SN7GT – CV925

DL63 (Dual Triode) Sensibly equivalent to:- CV2912 – DH147 – 6R7G – OM4

U18/20 (Rectifier) Sensibly equivalent to:- 45IU – AU1 – CV1264 – FW4-500 – NU12 – FW4-800 – CV31 – 4/100BU – RV200/600

U50 (Rectifier) Sensibly equivalent to:- 5Y3G – CV1268 – CV3754 – 5Y3G/GT

L63 (Triode) Sensibly equivalent to:- 6C5 – 6J5G – CV1067 – CV1932 – VR67 – VT154

H63 (Triode) Sensibly equivalent to:- 6F5G – CV1073 – VT73