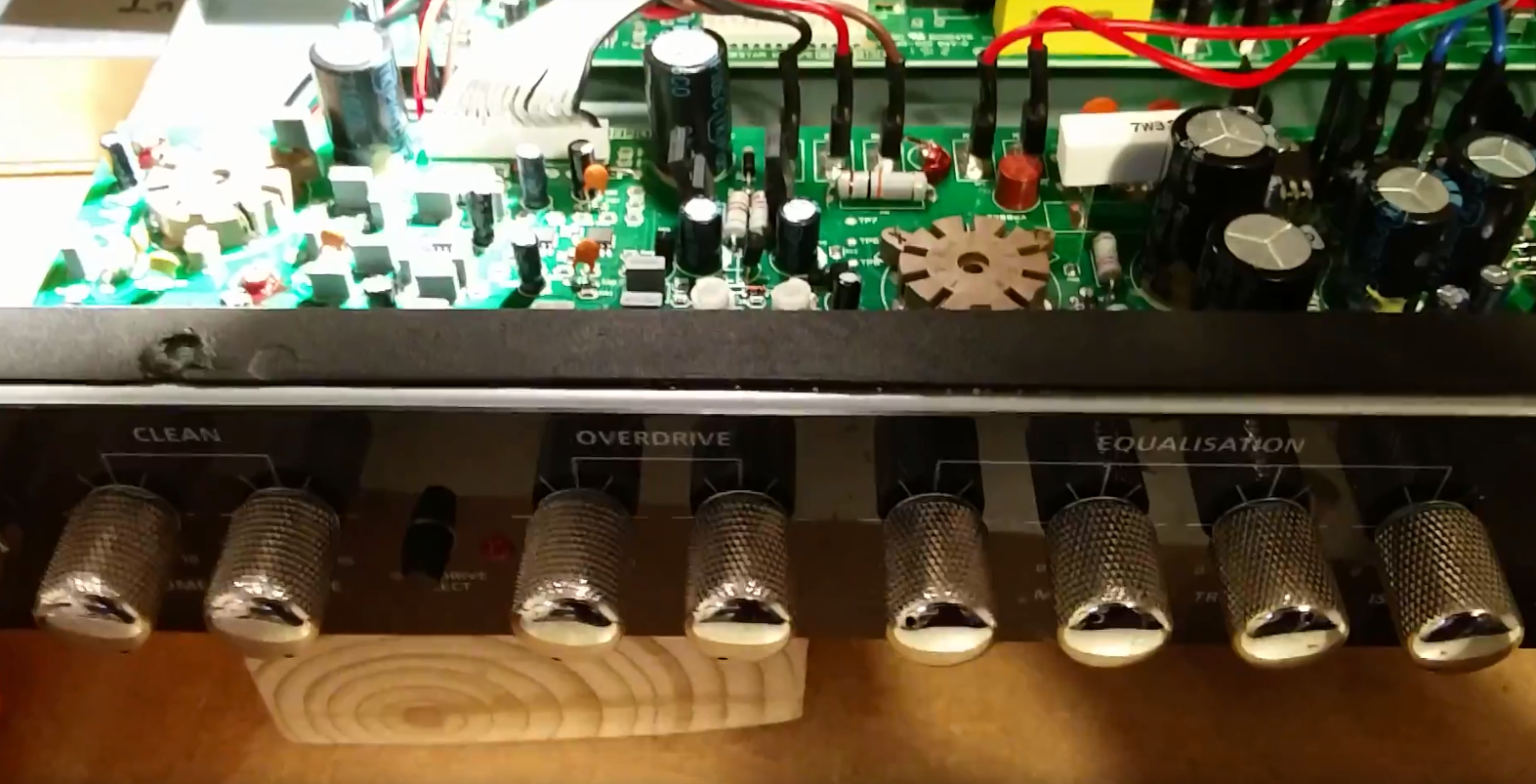

I thought I ought to document this Yamaha THR repair whilst I could still find the photos!

The amp had fallen from a height and the DC power input socket was damaged. Simple enough job, or it should be! Yamaha supply a an external converter to convert the mains supply into useable DC, but they use a non standard DC plug. (Note: some call it a mains socket, but it isn’t fortunately! 🙂 )

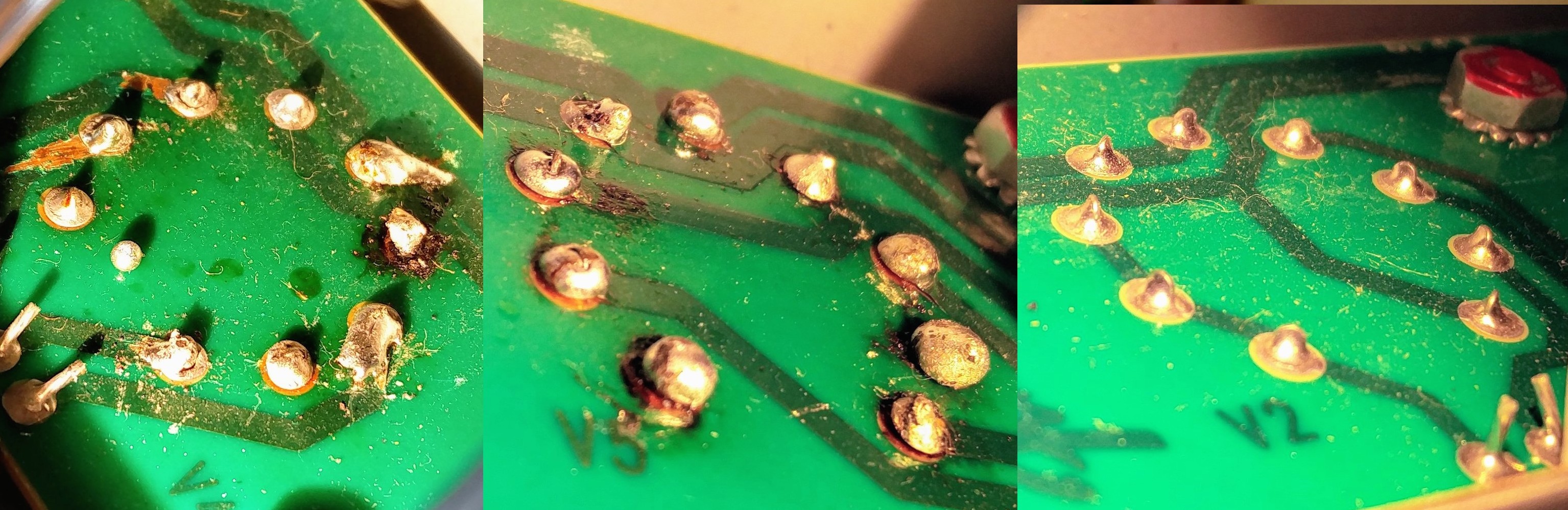

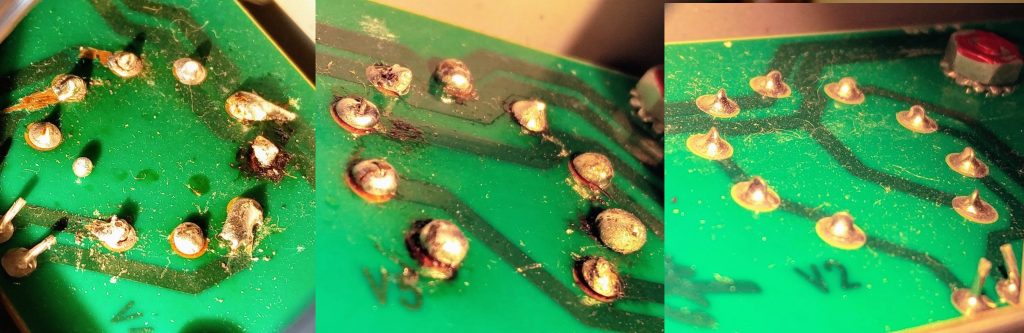

The photos show: Yamaha’s little class D amp, my PCB/ DC socket modification top side, the Yamaha SoC and RAM, the marking for the case modification, the PCB modification reverse side and the second layer of boards.

These are cool little solid state modelling amps. Sadly, for such an otherwise great company Yamaha aren’t very good at supplying spares so I was forced to fit a different socket and slightly modify the THR case to make it fit.

If you need a Yamaha THR repair, please contact me.

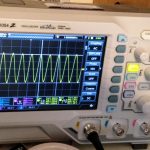

Here’s a video: