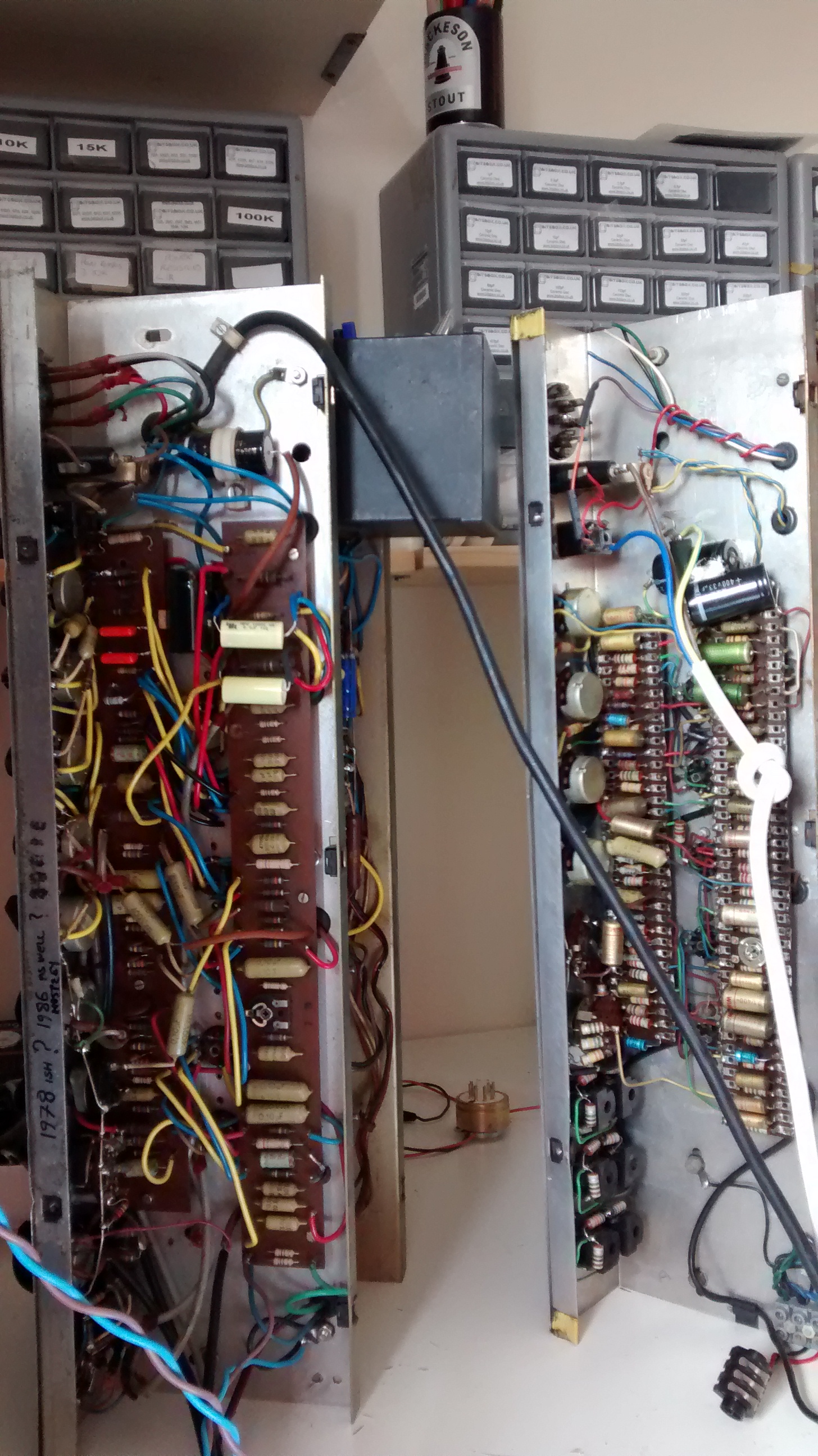

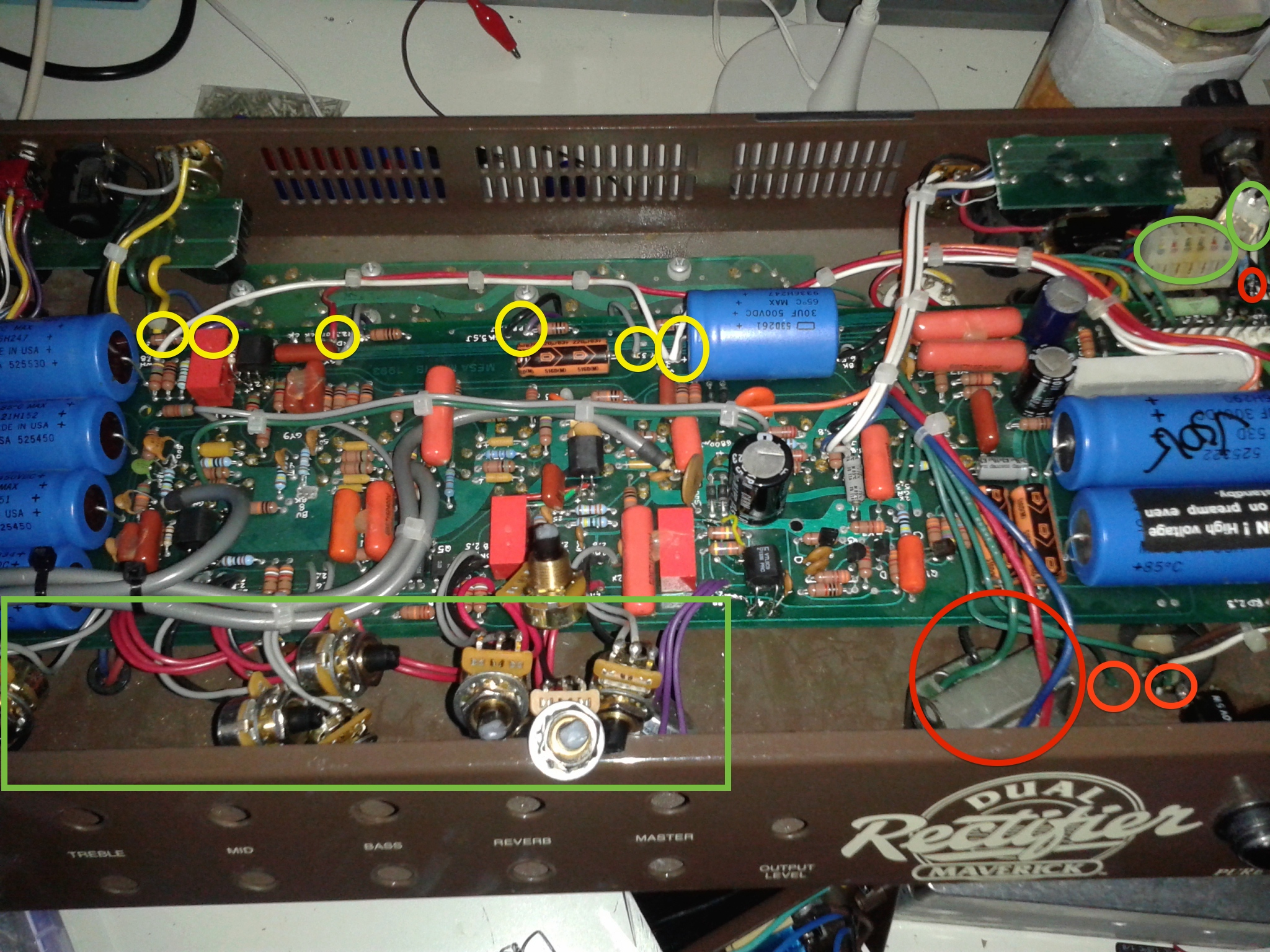

Shortly after the Confetti 1962 vintage ac30 repair arrived, this vintage Vox repair turned up on my bench too! The 1961 in the picture is on the right, the left amp is a 1970’s vintage vox, which you can read about here.

This is (as far as I can tell) a 1961 model. It was once covered in a cream vinyl, but the customer (who had it from new!) had decided at some point that it would look cooler in black and painted it.(!)

After laying down his axe many years ago, the customer decided to sell the amp and brought it to me to service.

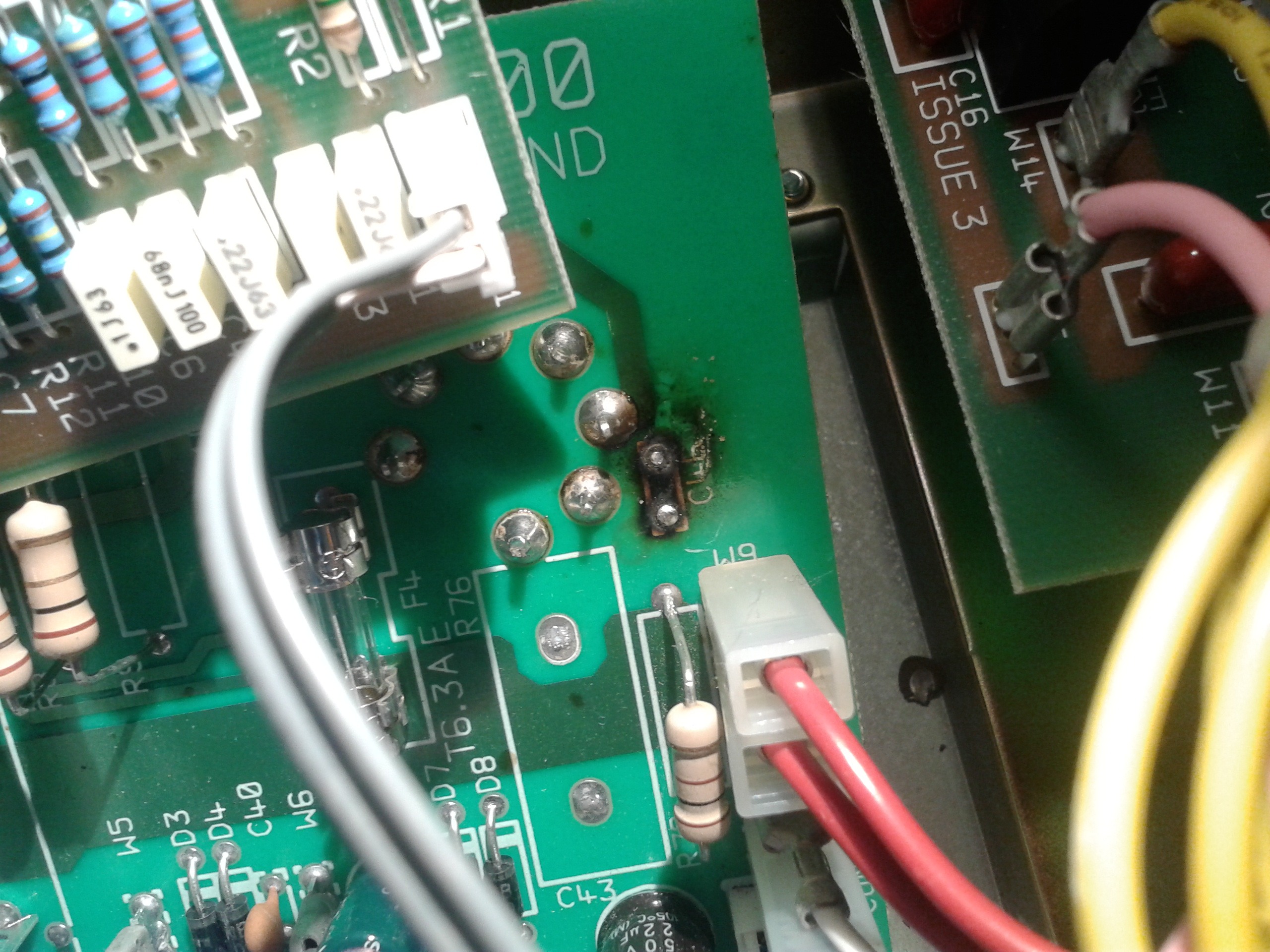

I found that the brilliant channel didn’t work. This turned out to be an out of tolerance resistor in the gain stage and a faulty coupling capacitor. Also the tremelo system wasn’t working. In vintage vox circuits, this consists of 6 triodes worth of analog electronics. 2 are an audio input buffer, 2 create a modulating signal and 2 mix the modulation with the audio signal. The fault was with the modulation circuitry and was again down to a worn out capacitor. This is not an uncommon task in vintage Vox repairs.

As with the Confetti 1962 vintage ac30 repair, I hard wired the mains to 245V for UK operation and replaced the ancient power cord with a modern tri rated mains lead.

I’m pleased to say that the customer was very happy with the vintage vox repair! If you have a Vintage ac30, or a vintage amp in need of repair, please get in touch.