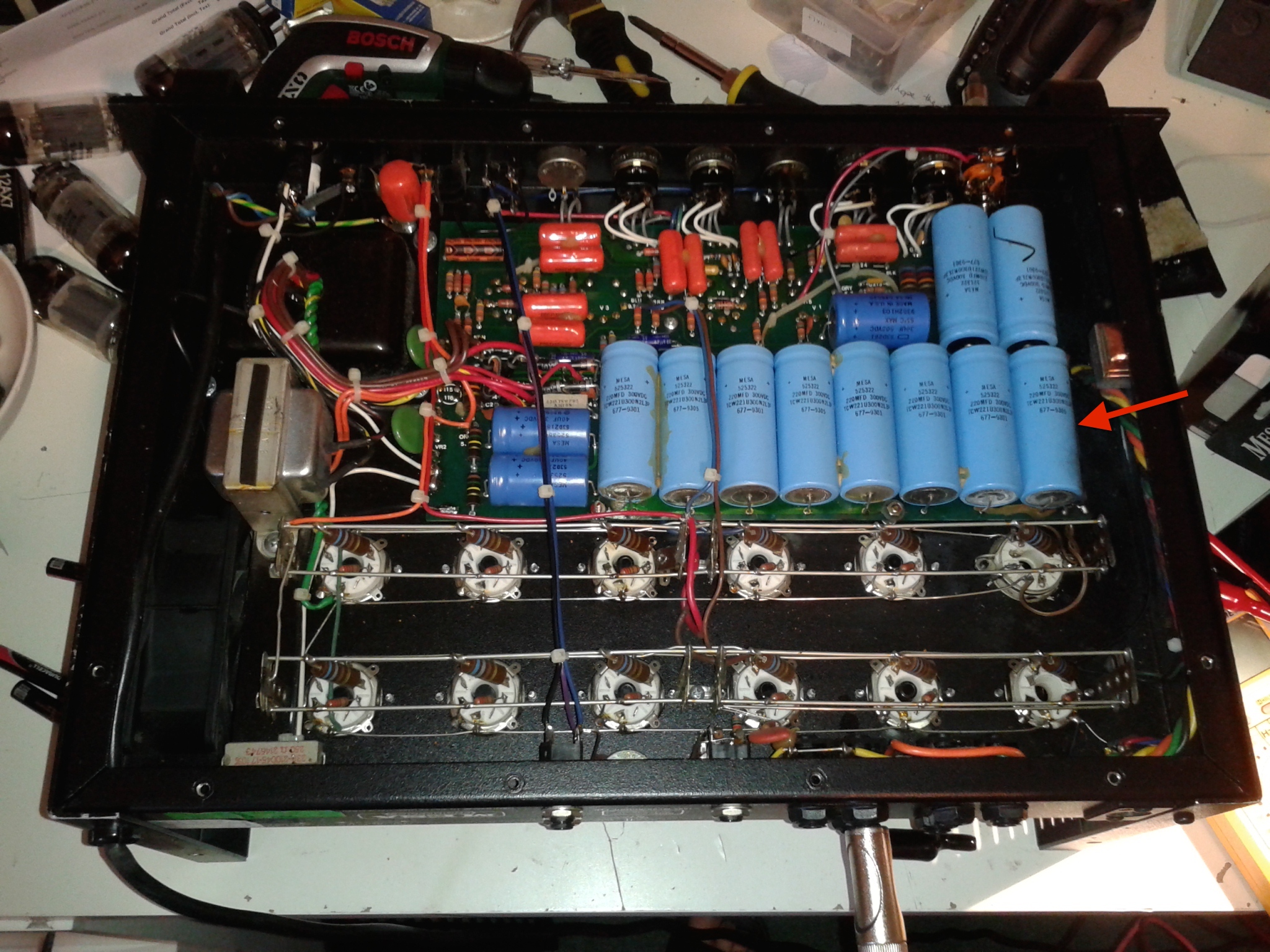

Another first for Keld Ampworks – the first AMI Jukebox repair. I’ve turned down jukebox repairs in the past because I naively had visions of a 7 foot unit arriving in my rather small workshop! This customer was quick to clarify that the amp unit itself is quite small and transportable from his Lincoln location. Nonetheless he sent me some pics of the full unit (above).

It is a US unit, bearing original battle scars and running on 110V through a transformer.

It is a US unit, bearing original battle scars and running on 110V through a transformer.

It was exhibiting a loud hum and excessive breakup. The customer asked me to do a basic valve test and check over and then report back.

It runs a preamp with one 12AU7 and one 12AX7, then a 12AU7 cathodyne phase inverter and a cathode biased 6L6 pair. One 12AU7 tested faulty (replaced with a valve from the customer’s collection), but the main problem was down to the badly worn 6L6 pair (replaced with a brand new matched pair of Russian EHX valves).

US amp manufacturers in the ‘old days’ didn’t tend to Earth their amps. All amps that leave my shop should have correct earth, fusing and safety practice so I fitted an external earth to this unit. Since the unit goes inside another unit this was fitted with a flying lead and solder tag to screw to the main chassis.

This is a favourite toy of the customer’s grandchildren and I’ve since heard that they’ve given it a thorough testing!

If you need an AMI jukebox repair, please get in touch.