This Orange amp repair is a particularly shocking example of an amp which someone has attempted to repair without really having an understanding of what they’re doing. The customer brought it to me with two issues: a broken reverb (victim of the botched repair) and an intermittently faulty gain channel.

I started out by performing a basic valve amp service upon the amplifier. This involves testing all the valves with my valve tester. 3 preamp valves were found to be faulty: this proved to be the cause of the gain channel dropout. This Orange amp repair didn’t require checking of the bias of the amp, because the Rockerverb MK II has Orange’s proprietary ‘DIVO’ power valve management, meaning that the amp biases itself. It’s the only system that I’m aware of that doesn’t require matched valves in the output stage, so when one of the EL34s was found to have a snapped key on its base, I installed a 6L6GC in its place! I also fixed the snapped key so it could be used.

I started out by performing a basic valve amp service upon the amplifier. This involves testing all the valves with my valve tester. 3 preamp valves were found to be faulty: this proved to be the cause of the gain channel dropout. This Orange amp repair didn’t require checking of the bias of the amp, because the Rockerverb MK II has Orange’s proprietary ‘DIVO’ power valve management, meaning that the amp biases itself. It’s the only system that I’m aware of that doesn’t require matched valves in the output stage, so when one of the EL34s was found to have a snapped key on its base, I installed a 6L6GC in its place! I also fixed the snapped key so it could be used.

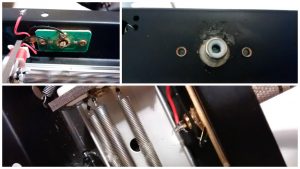

Turning my attention to the spring reverb repair, I noted that one of the phono cables had a broken connection. The connectors had been made up without any strain relief and this had allowed damage to happen during normal use. This is an easy fix and after fixing the broken connection I resoldered the other reverb intact connector so that both had adequate strain relief.

Upon testing the faulty spring reverb I discovered that it still wasn’t fixed so I turned my attention to the unit itself. Worryingly, one of the sockets was surrounded with glue on the outside. When I opened it up I realised that some fool(!) had tried to fix the loose socket by flooding it with superglue. Worse, as you can see in the picture the glue had dripped inside the unit and fouled the springs quite badly.

I was able to remove the superglue, but they remained quite distended. The unit still works as a reverb so my customer decided not to have me replace the tank.

If you’ve got an Orange Amp repair or a spring reverb repair, please don’t bodge it, just get in touch!