Aiming to bring some objectivity to a much debated topic, this time we’re talking about lead free solder in guitar amps.

“Do you use Leaded or Lead free solder at Keld Ampworks?”

Both.

In products that were built using lead solder I use lead solder. From a health/product recycling point of view it’s pointless to do otherwise.

In products that were built with lead free solder I use lead free solder. I DON’T use lead solder for these because if the two solder types are mixed they don’t flow together properly. They cool at different temperatures causing cracks in the solder and leading to long term reliability issues. If someone is repairing your amp and they’re using lead solder to ‘fix’ the lead free solder then they’re making it worse. Hope that hasn’t happened for you.

“But I’ve heard lead free sucks!?”

It’s probably worth addressing some claims regarding the use of lead free solder in the audio industry. Ten years ago I used to be a “lead free sucks” kinda guy too! But my understanding of the subject and my soldering skills have improved and so has the lead free technology – I no longer believe that modern lead free does “suck”. This post may border on a rant, so apologies in advance.

I’ll try and talk in general terms. This post’s intended audience is a guitarist with a soldering iron.

Solder is commonly made from a combination of Tin (Sn) and a mix of Lead (Pb), Silver (Ag), Copper (Cu), Nickel (Ni) in different ratios:

There are three common combinations:

- SnPb – Leaded solder was common worldwide until the 21st century. As I understand it is used for internal markets in the USA and China.

- SnCu – ‘Cheap’ Pb-free solder. Commonly used in budget Pb-free applications.

- SnAgCu – ‘Good’ Pb-free solder. The silver helps the solder to flow. Used in ‘good’ Pb-free applications.

For a number of health and recycling reasons, the EU (…pause whilst normally reasonable people from all political spectrums start fighting for no apparent reason…) introduced legislation in 2003 that had to be enacted by 2006. This legislation was called RoHS (Restriction of Hazardous Substances). As you’d expect because of purchasing cycles, some manufacturers switched before the introduction date. Others didn’t prepare, or didn’t know how to.

The early days of Pb-free adoption (early 2000s) saw some serious problems, especially using lead free solder in guitar amps. Lead solder had been around for 100 years. Problems were to be expected in the first few years of a new technology. In our small industry, many brands build their products in house rather than paying specialist electronic assembly subcontractors companies to build their products. This meant that the music industry was slower to fix lead free issues. They couldn’t afford to buy better machines, they couldn’t afford to hire expensive Pb-free transition consultants. So audio electronic products from the early 2000s had some problems, the results of which are still turning up on my bench now.

But this was almost 20 YEARS AGO. Machines got better, process control got better and these problems no longer really occur when using lead free solder in guitar amps (modern guitar amps). This is my own experience and also the opinion of the vast majority of assembly houses and manufacturers. I’ve been doing repairs since 2008. The early crop of Pb-free failures were already surfacing. As time has passed, the Pb-free related issues I’m seeing mostly stem from that early crop of amps. Later (post 2010 to be cautious) Pb-free units don’t seem to have any more problems than their older SnPb relatives.

“Lead Free Causes cold solder joints!”

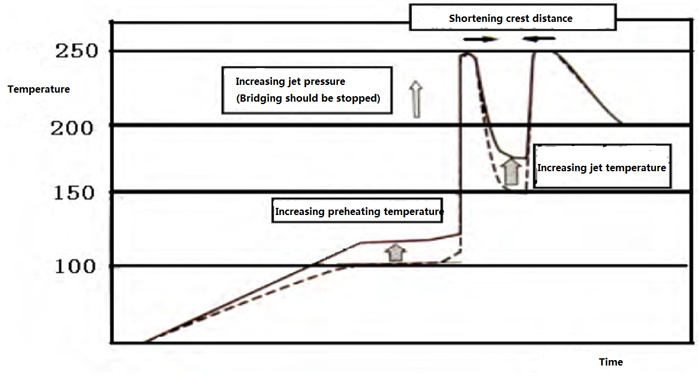

The risk of cold solder joints in Pb-free was higher in the early days of Pb-free tech. But changes in manufacturing process and process control have now fixed those issues.

At first, some manufacturers simply tried to ‘turn up’ SnPb machines to a hotter temperature to use with Pb-free. This didn’t work and bad joint issues appeared *cough* early JCM2000s *cough cough*. Just ‘turning up’ the machines didn’t work because you need to make changes to the heating up process – a few extra degrees of board preheating, changes to timings etc. Over time all those old machines have been replaced with machines with temperature control loops that can cope with lead free tech.

In another life I worked with several sub contract PCBA companies who made lead based and products alongside lead free. Every one of them has voiced the opinion is that the joints on modern Pb-free tech are on a par with those on modern SnPb tech and are BETTER than those of older SnPb tech. Almost 20 years into RoHS, this is to be expected. If you’re working with a manufacturer and they’re telling you to use lead free to improve reliability, then ask yourself what else they’ve missed from the last 20 years.

“Lead free solder in guitar amps causes Tin Whiskers”

This is a piece of largely irrelevant doom mongering. Tin whiskers are a real thing, but they’re not a significant risk in properly made guitar products in 2020.

The actual cause of tin whiskers is unknown, but they have always existed in tin based electronics – they happen in lead based products too. Anything with tin with impurities can have tin whiskers. Once again tin whiskers problem got much worse when Pb-free tech was in its EARLY stages. Those issues have once again been overcome by changes in process control. It transpires that if you change the rate at which lead free solder cools (annealing) then the risk of tin whiskers is substantially reduced. Tin whiskers still happen and are still slightly more common in Pb-free, but the serious cases relate to early Pb-free tech.

Tin whiskers are very very very small. They’re referred to as spanning ‘long’ distances in technical documentation and science journalism, but that’s because to someone who spends their technical life looking at PCBs under a microscope 0.5mm is ‘very long’. The very extreme cases are a couple of mm or so. ‘Normal’ lengths are micrometers long and they primarily affect fine pitch SMD. But the “lead-free sucks” adherents usually consider SMT to be against their religion anyway. 😀

However even for these SMT applications, there’s a benefit to Pb-free. Because it doesn’t wet as well as SnPb, Pb-free creates a greater angle on component leads. This has helped with the solder-ability of fine pitch ICs.

For manufacturers still worried about tin whiskers, then the solution regardless of whether you use SnPb or Pb-free is to conformal coat the board. Conformal coating is like a sort of PCB varnish. It isn’t a nice process and should only be attempted with appropriate PPE, but as well as being a good way of reducing tin whisker growth it has the more useful advantage of water-proofing the PCB. An audio product is significantly more likely to die from beer than tin whiskers so this is of real benefit to our products.

“What is a good Pb-free solder?”

The important things are to get a Pb-free that is SnAgCu (Tin, silver, copper) rather than just SnCu (cheap option). The addition of silver helps it to flow. Also lead free requires a higher flux content (2% or greater, by weight) to wet properly. Because they’re higher flux content is makes sense to use a solder with a no-clean flux.

Other than that, just look for a known brand sold by an reputable electronics company so that you know that what it says on the label is actually true. So Kester, or Loctite, Multicomp from Farnell, RS Pro from RS etc will be fine provided they’ve got the above specs. Amazon or eBay or Aldi or Lidl ( 😀 😀 ) may not be!

I use SAC305. This contains 96.5% tin, 3% silver, and 0.5% copper. My Pb-free solder has 2.2% no clean flux.

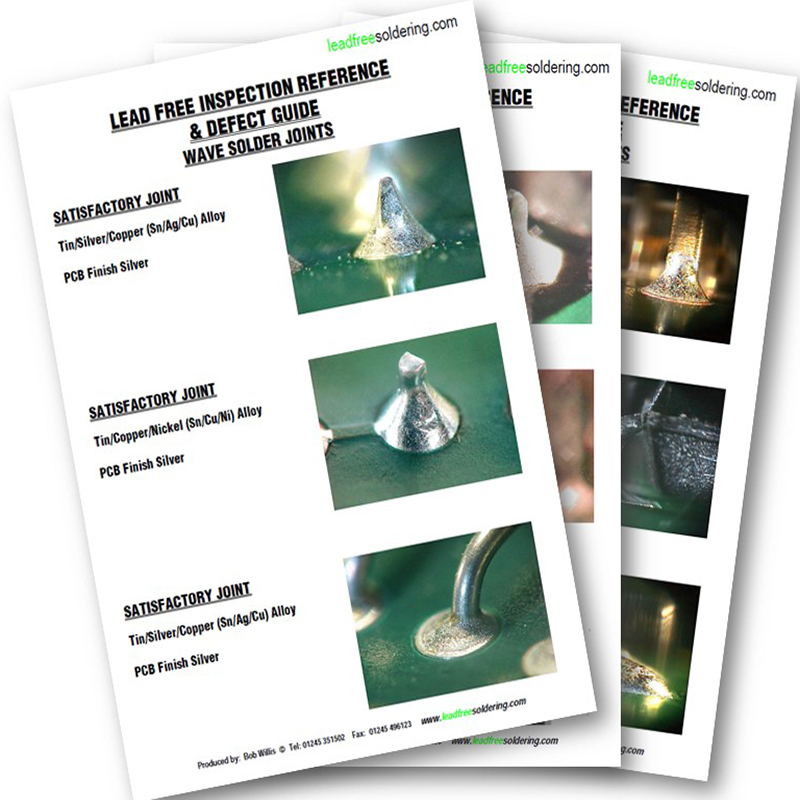

“Lead free doesn’t make shiny joints”

You got me. The joints won’t look as nice. They won’t be shiny and they will have dapples and marks. But they will be electrically sound if done properly. There are process control experts who show how to identify an acceptable joints with Pb-free solder. It’s just about knowing how to do the job properly. If you’re desperate for a shiny joint then you can use a SnNiCu lead free. These aren’t readily available but the addition of the Nickel makes it shinier.

“It’s not as ‘fun’ to use.”

Nope. May as well be honest about that. If soldering is your idea of fun then Pb-free does indeed “suck”. But it is electrically fine. Using SnAgCu helps, as does higher flux content.

“The Military/Aerospace won’t use lead free because it sucks, so why use lead free solder in guitar amps”

OK, ignoring for a minute the absurd idea that a guitar amp should be designed to the same spec a rocket.

At the end of their product lifecycle, Military, Medical and Aerospace electronics have their decommissioning dealt with by experts in their fields. This is why they are exempted from legislation. Those experts know what’s in the products they’re decommissioning so it essentially doesn’t matter what they’ve got in them (within reason!). When processing consumer waste at your local recycling centre the processor doesn’t have that info so they need to be able to make assumptions about what chemicals are in a guitar amp. So if a guitar amp is CE marked then it’s assumed not to have lead in it. If it’s not CE marked, then it’s assumed to have lead in it.

This is why if you go down to your local dump then you won’t find the SpaceX prototypes lying around. I know you’ve been looking.

“It kills soldering iron tips”

True. Tips will degrade faster because the higher tin content reacts with the iron plating on the tips.